Boyer & Associates has recently run into a number of sand mining businesses that have outgrown their Quickbooks systems. Sand mining for the oil fracking businesses in North Dakota is an industry that has exploded with most of the sand mining operations in Wisconsin being able to sell all of the sand they can produce. In fact, most of the mines don’t compete because they all have the unique issue of being able to sell all of the inventory they can produce. The constraint is in getting it to its North Dakota or Texas location, usually by railcar.

Here are some of the issues we’ve been able to consult on and plan a resolution for with sand mining firms needing more robust systems:

- Creating a workflow for approving purchases. Many of the sand mining firms heavily rely on contractors, so getting an easy way to approve spending someone else’s money is important.

- Improving service management to control contractual agreements, service level commitments and warranties.

- Many sand mining businesses have both a wet plant and a dry plant, depending on their processing needs. Some only need their processes evaluated at one plant or the other.

- Production Business Intelligence “Cubes” of data are often needed to evaluate shipments and production.

- Integrating with programs that weigh cars and handle logistics (e.g., BNSF Logistics has software with these capabilities).

- Creating a simple screen and report that allows sand mining firms to enter a railcar number, and then have a screen or report show history of activity for that railcar.

- Reducing the number of manual spreadsheets to track shipments, railcars, bills of material, work center productivity, etc.

- Addressing financial needs, distribution needs, field service needs, and manufacturing needs with one software solution.

- Creating multi-company entries as sand mines often have two separate firms – one for the distribution and one for the production. Often, there is a third firm to track real estate transactions. They tend to want one checking account (one set of checks with electronic payment options), but then have the system create the many due-to and due-from transactions among the firms.

- Addressing fixed assets needs is key as these firms have big investments in fixed assets and need the assets to be maintaining so they can stay up and running.

- Quickbooks users have the need to ship without invoicing, but they don’t have that feature in such a low end product. Dynamics NAV, for example, does this well and without the need to customize anything.

- Tracking blanket orders to ship from in-transit inventory.

- Providing the ability to reserve inventory by customer orders using a Purchase Order.

- Providing information about how much has been shipped or is in transit on any given PO.

- Maximizing the productivity of field service people with workflows that can be based on tablets and phones.

- Offering options for mixed-mode and make-to-stock manufacturers.

- Integration of procurement, production and services.

- Many sand mines need to track the history of how both leased and owned railcars have been used, and they also need to track inventory in transit by car. Please read below to see how railcar history can be tracked in Dynamics NAV by simply configuring creatively and without a customization.

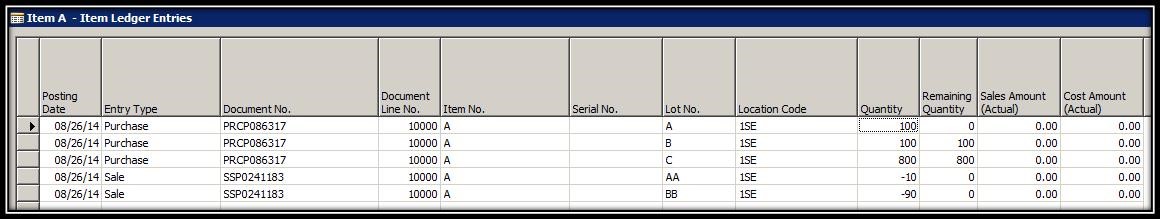

Use Item Tracking on Inbound Purchase transactions and Outbound Sales transactions only.

In this way, Dynamics NAV does not require you to consume inbound lots on outbound entries.

We are using Lot No.’s so a number can be used multiple times (vs. Serial No.). This allows you to enter an order line for a single quantity that would be filled in one to many cars (Lots) of certain quantities. For example, the process would be to enter a purchase order or sales order, and then, in item tracking for the line, enter the Lot No.’s (Rail Car No.’s). That way, when receipts/shipments are posted, you’ll be left with item ledger entries with Car No. (Lot No.) information.

So, as you can see, there are many issues that sand mining firms are trying to address in addition to their biggest issue of being able to move the sand as quickly as possible to their customers, so they can ship more sand.

I hope this information has been useful to you if you own or operate a sand mine. We are willing to consult with you for free to see if a solution, such as one of the middle-market Dynamics ERP systems, can work for you.

Please contact us with any questions, and visit our blog for additional tips and tricks regarding Microsoft Dynamics products.