Microsoft Dynamics NAV has a robust manufacturing capability with many features. In this series of blogs, we will address many of those features, starting with NAV’s Bill of Materials (BOM), which can handle a fifty level deep BOM.

In future blogs, we will address NAV’s routing design, which allows multiple products to share the same routing; how NAV allows for multiple versions of both the BOM and routing, with the ability to run a comparison report to the various BOM versions of an item; methods of collecting labor for production orders; how to track separate labor and burden costs on production operations; and the requisition functionality within NAV as it relates to production orders. The blogs will also cover the detailed historical information that is stored within NAV as it pertains to production orders and how that information can be analyzed to better estimate and plan future orders.

Microsoft Dynamics NAV Bill of Materials

Microsoft Dynamics NAV’s manufacturing capability includes a Bill of Materials Design that is powerful, functional, and easy to maintain. The BOM is tied to the item card, and more than one item could share the same BOM. This functionality can simplify the maintaining of BOMs.

The key features of NAV’s BOM are:

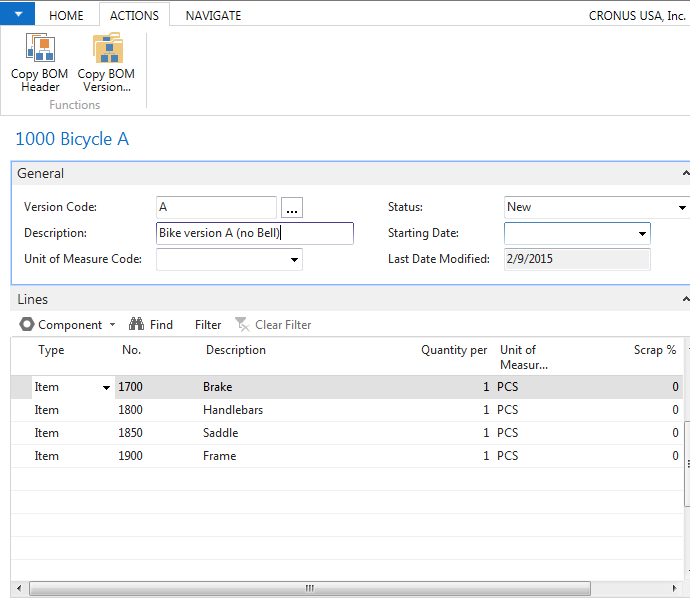

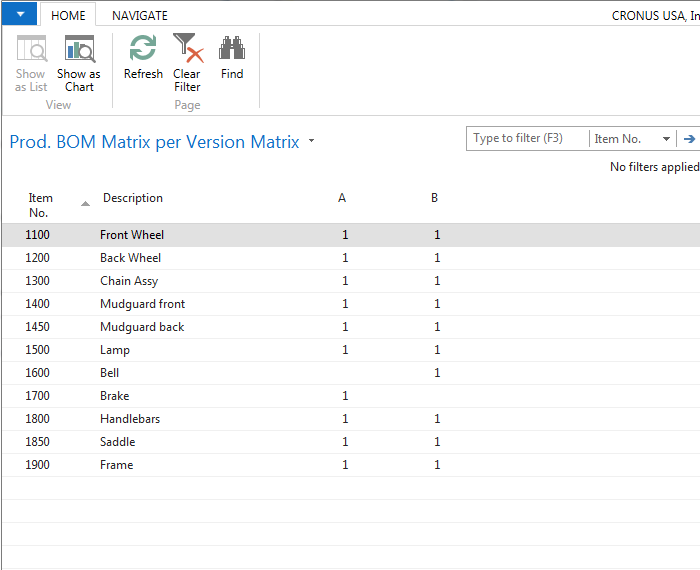

- The ability to save versions of an item’s Bill of Materials. This functionality is great to track the history of the design of an item, and it also allows for alternative BOMs to be used when necessary. This feature is also great when clients will request an item using an earlier BOM for a particular reason. NAV’s BOM includes the functionality to copy a BOM or a version in the creation of a new BOM.

- The ability to compare versions of the BOM to identify differences. Each line of the BOM can be an item or another BOM. NAV can handle up to a 50 level deep BOM, which is far beyond any BOM I have worked with in my 30 years in manufacturing software.

The NAV Bill of Materials functionality is a key reason NAV is a good choice for the manufacturing company. Be sure to subscribe to our blog so you don’t miss future posts in this series on manufacturing features, as well as other tips and tricks on Microsoft Dynamics NAV.