I am always amazed when I visit a Microsoft Dynamics NAV user who has been on the system for a while and I find that their purchasing department is not taking advantage of the Requisition Worksheet capabilities of NAV. Often, I hear it is too complicated or there is a fear of loss of control in the requisition process. Both of these could not be further from the truth.

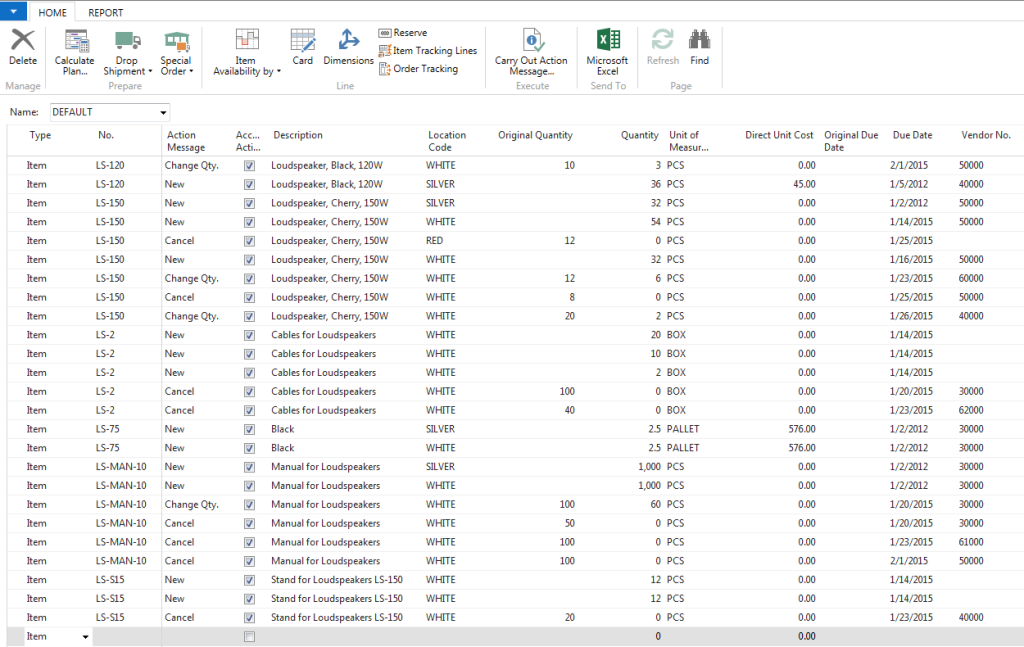

What the NAV Requisition Worksheet does is move the requisition process from being reactive to being more proactive. Through the proper setup of controls on an item and the maintaining of those controls based on changes in that item’s environment, companies have a tool that will suggest what, when, and how much to buy. All of this information is the result of what is setup in the item card and the demand entered into NAV through Sales Orders, Production Orders, and Inventory Item setup. Microsoft has even added dampers per item to limit the number of action messages for an item based on minimal changes in demand or schedule.

The average administration cost of a Purchase Order (not counting items purchased) for a distribution company is $150.00 per Purchase Order. Balancing this with the carrying cost of inventory is the trick to increased profits and happy customers.

The thing to note with NAV (or any requisition system) is that it will tell you what to order, but it cannot get rid of what you have in overstock. Companies will often implement the Requisition Worksheet and notice that if they follow the suggestions of the system their inventory will go up. This is the result of current overstock situations, and although NAV can identify them, it takes a plan to eliminate them. What users find is that after an initial increase in inventory (normally minimal), they see their inventory levels drop over time while Sales Order fill rates improve. In one case, the owner of a company told me the reduction of inventory may have been the result of his purchaser getting better at the job; however, the increased fill rates were the result of NAV’s Requisition Worksheet identifying what is required for Sales Orders.

Through the proper setup of items, the user can control when, how many, and from whom items are ordered. Additional controls handle safety stock levels, dampers for quantity and schedule changes, lead times per vendor, and cost per vendor. Initiating this process moves the requisitioner’s time from figuring out what to order to maintaining the items and reviewing what the system says to order. It should be noted that many companies will have a few items that do not plan well – they may have characteristics that do not lend themselves to a planning tool. The time to watch these items is easier when most requirements are being tracked effortlessly through NAV.

Keep in mind the Requisition Worksheet is only going to make suggestions. The user has the final word and control over what is ordered, how much, and from whom.

For additional tips and tricks regarding Microsoft Dynamics NAV and other Dynamics products, check out other informative, useful blogs on our site by clicking here.